Encraving

★★★★★ Rated 5 out of 5

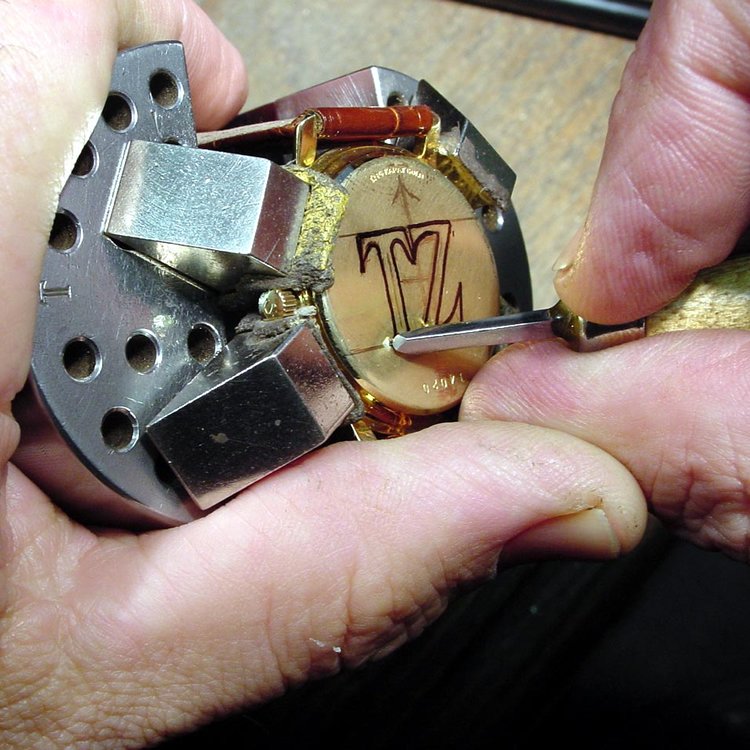

Everything can be engraved. Different methods will yield different results. Each graver is different and has its own use. We use a hardened steel tool called a burin, or graver, to cut the design into the surface, such as silver, nickel, steel, brass, gold, titanium, and more, in applications from weaponry to jewellery to motorcycles, watches to found objects.

We also use a Stereo microscope for the fine work like signet rings.

Share you signet ring design or other design that you would to be created individually for you!

We Specialize in the Following:

Hand Engraving:

Hand engraving is done completely by hand, it requires a basic, burin machine that holds the item being engraved and guides the engraver through the fonts using strong and sturdy metal guides. it allows for deeper engraving and that it will last longer.

Machine Engraving:

This is the prefered tool for flat pieces and logos. Most engraving machines are limited to engraving flat pieces, it offers a better quality of engraving and is less labor intensive, therefore less expensive.

This is the prefered tool for flat pieces and logos. Most engraving machines are limited to engraving flat pieces, it offers a better quality of engraving and is less labor intensive, therefore less expensive.

Laser Engraving:

The precise power of a laser beam is most prized but is not available for everything. This is the preferred method of engraving logos, because the vectorizing of logos required by engraving machines is not necessary (in most cases) and formats like jpeg or gif can be used as is. The speed of the laser makes it attractive to engrave bulk orders. Being connected to a computer, it offers a wide variety of fonts.